Technicial Specifications

| Gross Power | 34.1 kW |

| Displacement | 2.21 l |

| Engine Model | Cat C2.2 |

| Standard Paving Width | 1400 mm - 2600 mm (4.6 - 8.5 ft) |

| Paving Width Minimum | 150 mm |

| Paving Width Maximum | 3400 mm |

| Maximum Travel Speed | 3.2 km/h |

| Truck Entry Width | 3 m |

| Hopper Capacity | 3.1 m³ |

| Maximum Paving Speed - With Vibratory Screed | 33 m/min |

| Truck Dump Height | 0.58 mm |

| Inside Turn Radius | 0.7 m |

| Maximum Operating Weight | 4500 kg |

| Operating Weight - With Screed | 4500 kg |

| Maximum Paving Speed | 33 m/min |

| Fuel Tank Capacity | 65 l |

| Hydraulic Oil Tank | 73 l |

| Cooling System | 17 l |

| Hopper Capacity | 3.1 m³ |

| Track Contact Length | 1.38 m |

| Overall Height | 2.5 mm |

| Inside Turn Radius | 700 mm |

| Maximum Height | 2.5 m |

| Transport Width - Hoppers Raised - Screed End Gates Attached | 1.6 m |

| Transport Height | 1.74 m |

| Length - With Push Roller and Screed | 4.2 m |

| Tractor Operating Width | 3 m |

| Length - With Push Roller and Largest Screed | 4.2 m |

Advantages and Features

Undercarriage

The machine's tracked undercarriage, fitted with heavy-duty rubber bonded pads, provides excellent stability and weight distribution minimising the negative effect of an uneven base. Track tension is assured by two grease pistons with a shock absorbing system.Cat® C2.2 Engine

Reliable Cat® C2.2 engine provides ample power and is EU Stage IIIb and U.S. Tier 4 Interim emissions compliant.AS3143 Electric Screed

The electric heated screed is powered by an onboard generator with independent temperature control in all four sections. Three heating elements for each screed section ensure uniform heating over the entire screed plate.Material Feeding System

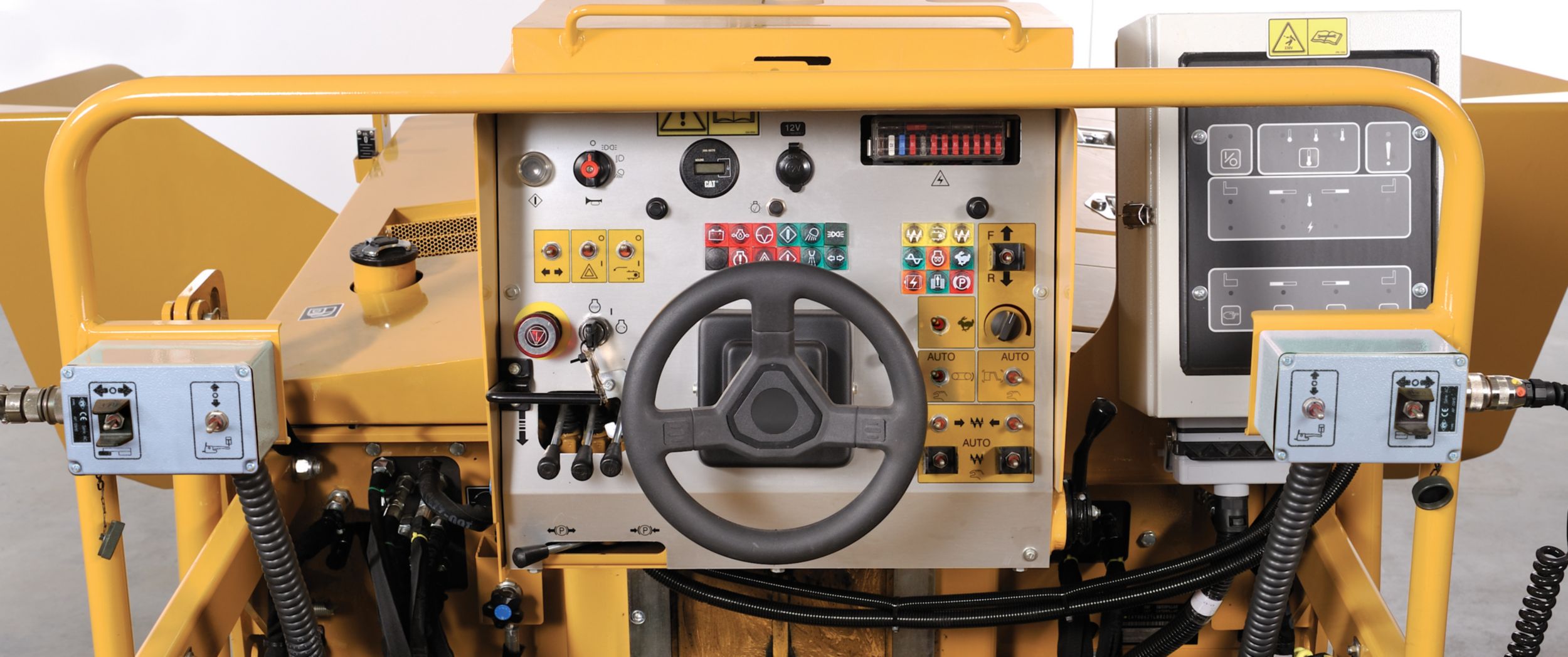

The hoppers are hydraulically operated and independently controlled facilitating applications close to walls or other vertical objects. The asphalt mix is carried to the screed by a heavy-duty steel conveyor and is distributed by two independently controlled augers, with reversible rotation. Three automatic material feed sensors provide correct amount of material to the screed. Augers can be hydraulically raised to avoid obstacles, facilitate machine loading on trailer and assembly of the paving width reduction option group. Conveyor and augers are reversible.Operator's Platform

The operator drives the paver from the platform positioned behind the screed. The console panel is fully equipped with comprehensive controls allowing a single operator to conveniently monitor all machine functions. The operator platform is fitted with an operator presence detector enabling machine functions when the operator is in the driving position.Serviceability

The AP255E ensures excellent access to all machine parts requiring scheduled maintenance. Large access doors provide quick and easy inspection of main components.Optional Equipment

- Power supply, 110V or 230V

- Grade & Slope Control

- Mechanical Feed Sensor

- Central Paving Width Reduction Package - 0.5 m to 1.40 m

- Right Side Paving Width Reduction Package - 0.15 m to 1.00 m

- Mechanical (bolt-on) extensions to reach 3.40 m paving width