Technicial Specifications

| Operating Weight - Standard Machine Empty | 10000 kg |

| Operating Weight - Maximum Ballast | 27000 kg |

| Compaction Width | 2090 mm |

| Number of Wheels | 8 |

| Travel Speed - Maximum | 19 km/h |

| Turning Radius - Inside | 6100 mm |

| Turning Radius - Outside | 8700 mm |

| Ground Clearance | 260 mm |

| Engine Model | C4.4 |

| Gross Power | 98 kW |

| Overall Length | 5350 mm |

| Overall Width | 2160 mm |

| Height - ROPS | 3000 mm |

| Tires | 13/80 R20 |

| Fuel Tank Capacity | 270 l |

| Water Spray Tank Capacity | 380 l |

Advantages and Features

Compaction Performance

- The eight wheel rubber tire roller delivers a compaction width of 2.09 m (82") and operating weight range of 10 000 kg to 27 000 kg (22,050 lb to 59,525 lb)

- Ballast options include 6.5 metric tonnes (7.1 U.S. tons) of modular steel, 6.1 metric tonnes (6.7 U.S. tons) of non-modular steel, and a 3000 liter (793 gallon) water-tight chamber, providing versatility to match job site requirements.

- Front and rear wheel sets oscillate and provide vertical suspension to minimize bridging that can occur on uneven surfaces.

- Optional air-on-the run utilizes a single-point air-fill that balances tire pressures to help meet quality targets and job site requirements.

- Edge management options include a cut-off wheel that a creates a vertical edge and a bevel edge that helps provide smoother transitions on and off the paved surface.

Pickup Prevention

- The standard pressurized water spray system with a capacity of 380 L (100 gal) is equipped with triple filtration and adjustable, intermittent spray settings to help manage flow.

- The optional emulsion spray system with dedicated 40 L (10.5 gal)tank, lines and spray bars provides utilization of release agents on the wheels for additional protection against asphalt adhesion

- Each wheel is equipped with a spray nozzle, adjustable high-strength scrapers, and water-retention cocoa mats that help keep the tires clean.

- Optional thermal aprons trap heat to prevent asphalt and aggregates from adhering to the tires.

Comfort, Visibility, and Control

- The display with simplified navigational controls enables operators to customize screens to monitor current operating conditions including travel speed, fuel level, engine speed, and engine oil pressure.

- The pivoting operating station rotates 90º to either side to provide good visibility when working near obstacles.

- Touch-pad control provides easy activation of Eco-mode, propel-speed ranges, travel speed adjustment, and the tire spray system.

- ROPS are standard and can be equipped with an optional sun canopy.

Smooth Operating Powertrain

- Engines are available to meet regional emission requirements

- Eco-mode operates at 1900 rpm to reduce fuel consumption and lower sound levels.

- Exclusive two-speed hydrostatic propel system provides speeds up to 19 km/hr (12 mph).

- The electronic propel system is designed to shift smoothly between speed ranges while also providing the ability to coast for a fuel-saving enhancement.

- The deceleration pedal enables the operator to gradually reduce speed when retracting the propel lever.

Safer Operation

- Seat belt alert system utilizes a green beacon mounted on top of the ROPS to indicate when the seat belt is in use. In addition, an audible alarm and on-screen indicator help encourage safer operation.

- The standard 75 mm (3"), high-visibility seat belt allows for easier visual confirmation.

- The optional fore and aft camera system mounted on the front and rear of the ROPS provides outstanding visibility when approaching obstacles. The camera view is integrated into a dedicated operating display.

- Standard LED working lights located in the front and rear bumpers deliver fore and aft illumination.

- Optional auxiliary LED lighting mounted to the ROPS enhances overall job site illumination.

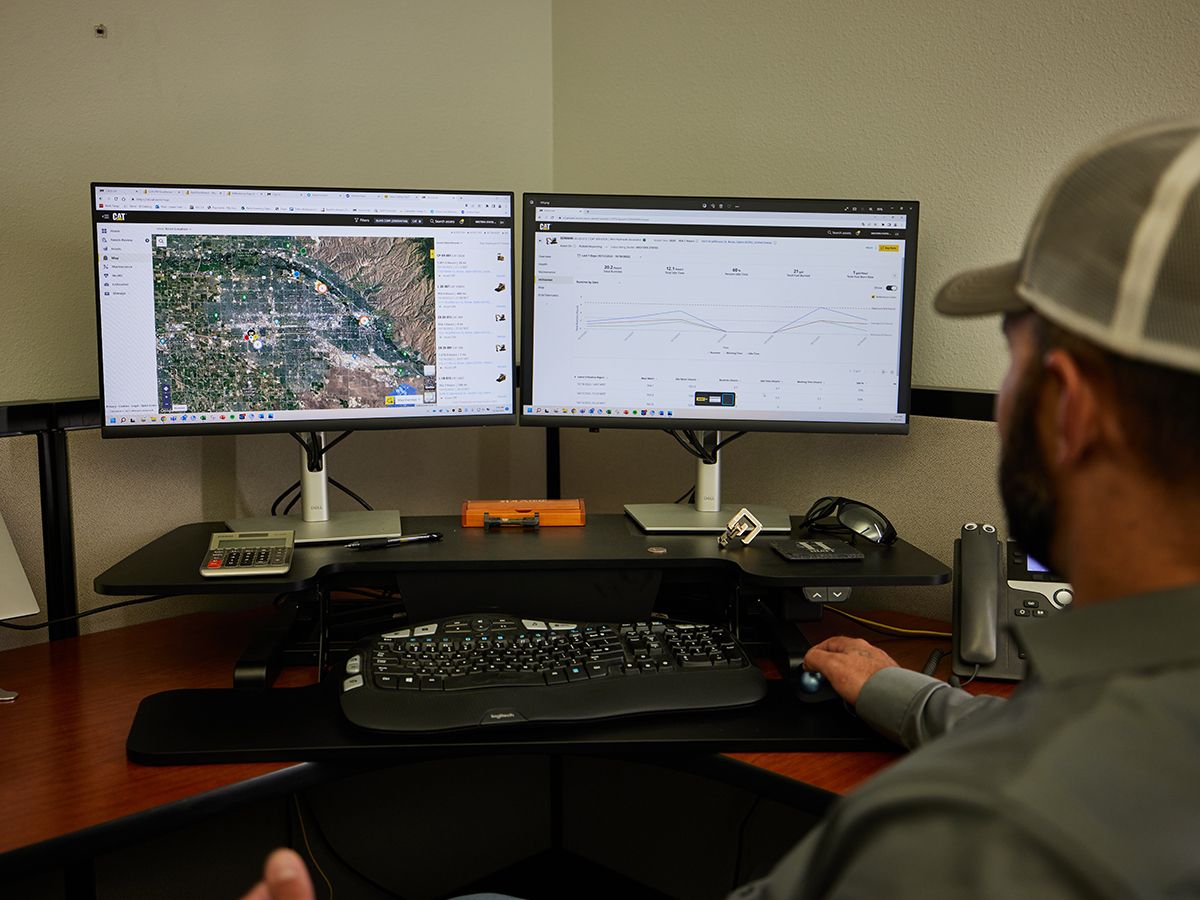

VisionLink™

- VisionLink™ is a cloud-based software application that provides data to your desktop or mobile device, taking the guesswork out of fleet management with key insights to maximize performance – regardless of fleet size or equipment manufacturer.

- The system provides maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and other machine data to your mobile device, desktop or through an API to other software applications.

Standard Equipment

-

Operating Environment

- Adjustable armrests

- Platform, ROPS/FOPS

- Power steering

- Rotating operator station

- Suspension seat, vinyl

- Vandalism protection

-

Technology

- VisionLink™

- Remote flash

- Remote troubleshoot

-

Powertrain

- Cat® C4.4, 4-cylinder

- Automatic idle shutdown

- Automatic speed control

- Variable-3 speed transmission

-

Electrical System

- 100 amp alternator

- 24-volt charging system

- Automotive-type fuse system

- Battery (2), maintenance-free

- Cat Electronic Technician, (Cat ET)

- Remote start/charge system

-

Wheels and Spray System

- All-wheel oscillation

- Front-wheel vertical suspension

- Pressurized water spray system

- Grouped filters with ground level access

-

Service and Maintenance

- Remote access drains

- Sampling ports for Scheduled Oil Sampling (SOS)

- Sight gauges

-

Safety

- Alarm, backup

- Horn, warning (front and rear)

- Rear backup light with stop indication

Optional Equipment

-

Operating Environment

- Air-conditioner, requires cab

- Cab, ROPS with heat and defrost

- Propel lever with 4-button control

- ROPS

- ROPS, sun canopy

- Seat belt, high visibility, 76 mm (3")

- Suspension seat, cloth

- Suspension seat, cloth, heated

- Suspension seat, vinyl heated

-

Technology

- Infra-red asphalt temperature sensors

- GNSS Mapping, Temperature and Pass-count

-

Powertrain

- Variable-3 speed transmission

-

Wheels and Spray System

- Ballast, factory installed steel blocks

- Cocoa mats, with scraper

- Edge management, cutoff, bevel

- Spare tire

- Steps, water spray refill

- Thermal tire aprons

- Tire inflation system, manual

- Tire inflation system, automatic

- Tires, 13/80 R20 MX C-1 Radial

- Tires, 11.00-20 TI 18 PR C-1 Bias

-

Service and Maintenance

- Hydraulic oil, bio-degradeable

-

Safety

- Lights, halogen

- Lights, LED

- Mirrors, external

- Roading lights with turn signals

- Working lights

Specalog

Specalog

Pneumatic Compactor Brochure

Pneumatic Compactor Brochure

Paving Product Line Brochure

Paving Product Line Brochure

Guide to Asphalt Compaction

This practical, hands-on reference manual covers the basic principles of asphalt compaction along with specific examples of how to use them effectively.