Technicial Specifications

| Engine Model | Cat® C18 |

| Gross Power - SAE J1995 | 439 kW |

| Gross Power - VR Engine - SAE J1995 | 439 kW |

| Gross Power - Tier 3 Engine - SAE J1995 | 439 kW |

| Bore | 145 mm |

| Stroke | 183 mm |

| Displacement | 18.1 l |

| Gross Power - Equivalent to U.S. EPA Tier 3/EU Stage IIIA - SAE J1995 | 439 kW |

| Note (1) | Power ratings apply at a rated speed of 2,000 rpm when tested under the reference conditions for the specified standard. |

| Note (2) | Ratings based on SAE J1995 standard air conditions of 25° C (77° F) and 100 kPa (29.61 Hg) barometer. Power based on fuel having API gravity of 35 at 16° C (60° F) and an LHV of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F). |

| Note (3) | Engine derate will commence at an altitude of 2700 m (8,858 ft). |

| Rated Power | 2000 r/min |

| Note (5) | Optional engine with emissions equivalent to U.S. EPA Tier 3 and EU Stage IIIA is also available. |

| Note (4) | Optional Ventilation Reduction package available. |

| Nominal Payload Capacity | 45000 kg |

| Gross Machine Mass | 85000 kg |

| Body Capacities | 18.0-25.1 m³ (23.5-32.8 yd³) |

| Empty | 40000 kg |

| Loaded | 85000 kg |

| Empty - Rear Axle | 12400 kg |

| Loaded - Rear Axle | 46240 kg |

| Empty - Front Axle | 27600 kg |

| Loaded - Front Axle | 38760 kg |

| Raise | 16 s |

| Lower | 21 s |

| Total Cycle Time | 37 s |

| Articulation Angle | 42.5° |

| Frame Oscillation | 10° |

| Outside Clearance Radius* | 9291 mm |

| Inside Clearance Radius* | 5310 mm |

| Note | *Clearance dimensions are for reference only. |

| Forward - 1 | 8 km/h |

| Forward - 2 | 10.9 km/h |

| Forward - 3 | 15.1 km/h |

| Forward - 4 | 20.6 km/h |

| Forward - 5 | 28.1 km/h |

| Forward - 6 | 38.1 km/h |

| Forward - 7 | 40.5 km/h |

| Reverse - 1 | 7.5 km/h |

| Reverse - 2 | 10.1 km/h |

| Note | Maximum travel speeds with standard 29.5 × R29 tires. |

| Engine Crankcase - With Filter | 64 l |

| Transmission | 60 l |

| Hydraulic Tank | 266 l |

| Cooling System | 85 l |

| Front Differential and Final Drives | 77 l |

| Rear Differential and Final Drives | 83 l |

| Fuel Tank | 764 l |

| Ejector Body | 22.9 m³ |

| Dump Body - 1 | 18 m³ |

| Dump Body - 3 | 25.1 m³ |

| Note | Heaped SAE 2:1. |

| Dump Body - 2 - Standard | 21.3 m³ |

| Tire Size | 29.5 × R29 |

| Standards | ROPS/FOPS Certified Cab |

| Differential Ratio | 3.46:1 |

| Final Drive Ratio | 5.65:1 |

| Total Reduction Ratio | 19.55:1 |

| Empty - Front Axle | 69% |

| Loaded - Front Axle | 45.60% |

| Loaded - Rear Axle | 54.40% |

| Empty - Rear Axle | 31% |

Advantages and Features

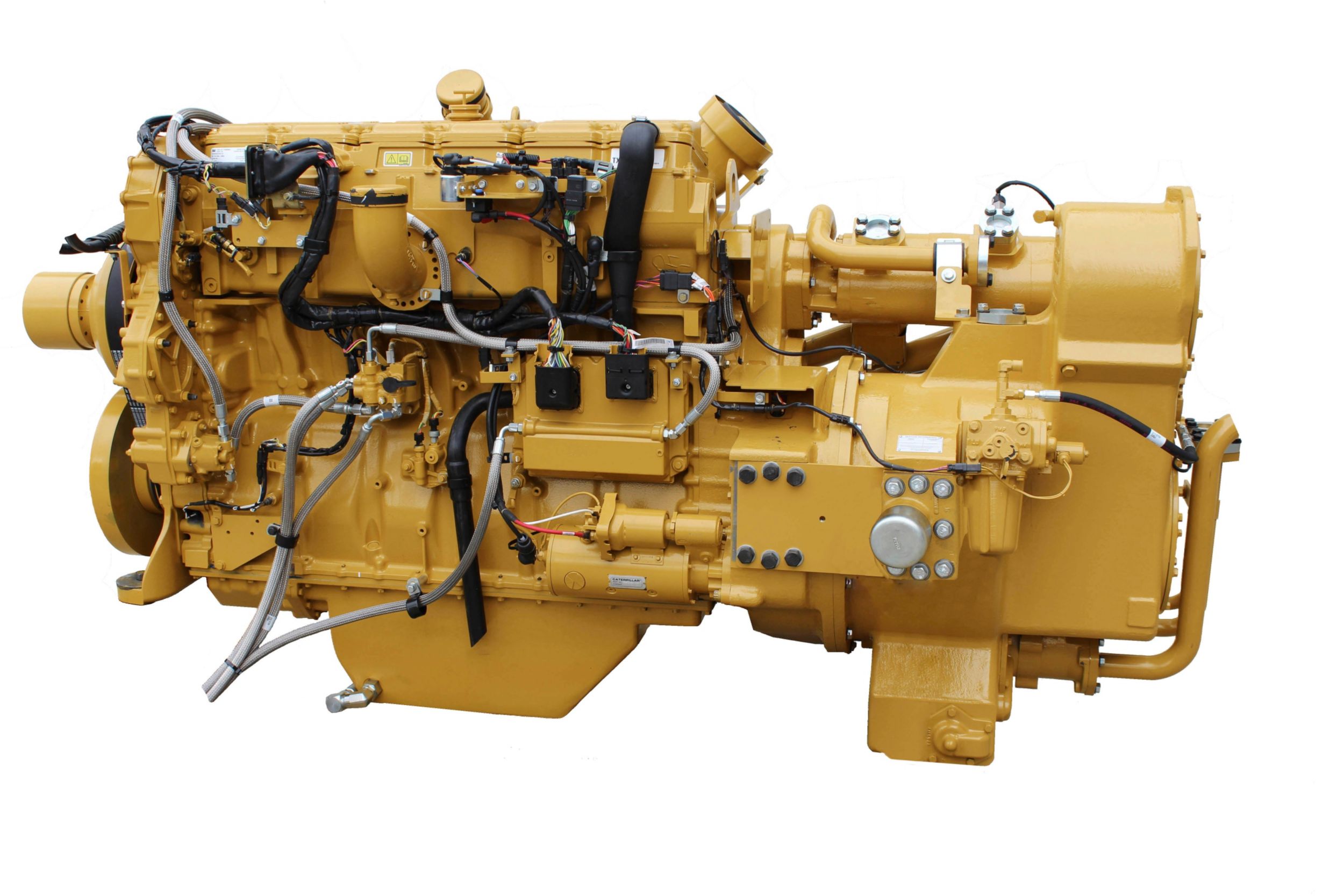

Power Train – Engine – The Cat C18 Engine is designed for power, reliability and efficiency.

The Cat C18 engine provides efficient fuel management for quick response, high productivity and exceptional service life. Torque rise effectively matches transmission shift points for maximum efficiency and fast cycle times. Mechanically Actuated, Electronic Unit Injection (MEUI™) high-pressure, direct injection fuel system electronically monitors operator demands and sensor inputs to optimize engine performance. Air-to-air aftercooling provides improved fuel economy by packing cooler, denser air into cylinders for more complete combustion of fuel and lower emissions. Turbo is water cooled to improve performance and service life.

The Cat C18 engine features the optional Ventilation Reduction (VR) Package. The VR Package incorporates selective engine hardware and software to minimize diesel particulate matter in the engine exhaust. Engines equipped with the VR Package feature a significant ventilation rate reduction, maintains fuel consumption, and maintained or improved product performance. VR Package availability is subject to regional regulatory compliance. Optional engine with emissions equivalent to U.S. EPA Tier 3 and EU Stage IIIA is also available.

A Cat Diesel Particulate Filter can be used with the VR engine package. This filter compliments the VR engine by further reducing particulate matter in the exhaust. Requires the use of ultra-low sulfur diesel (15 ppm) and CJ-4 low ash engine oil.

Power Train – Transmission

Mechanical Power Train

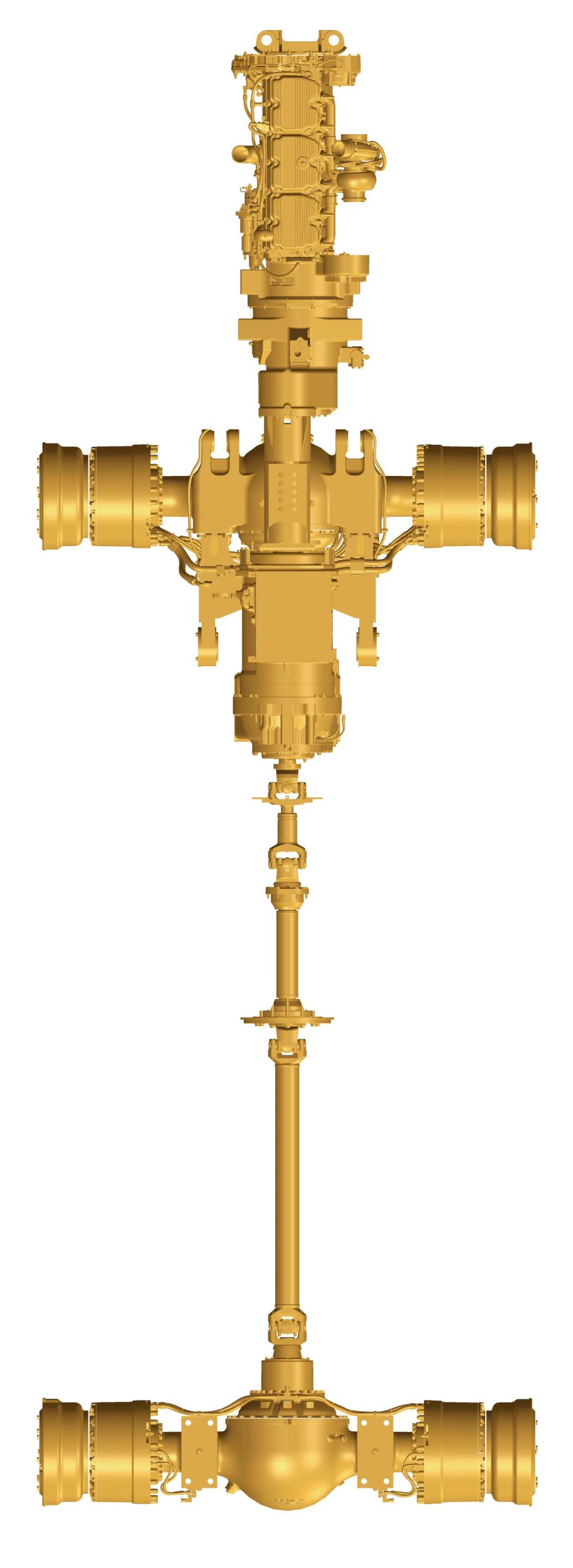

The Cat mechanical drive power train and power shift transmission provide unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads and drives with high rolling resistance.

Transmission

The Cat seven-speed planetary power shift transmission is matched with the direct-injection C18 engine with ACERT technology to deliver constant power over a wide range of operating speeds.

Robust Design

Designed for rugged underground mining conditions, the proven planetary power shift transmission is built for long life between overhauls.

Lock Up Torque Converter

Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. When engaged, lock-up provides superior power train efficiency by delivering more power to the wheels.

Lock-Up Clutch

Quickly releases and re-engages to reduce power train torque loads for smoother shifting, long life and a more comfortable ride.

Smooth Shifting

Individual clutch modulation provides smooth clutch engagements to optimize performance and extend clutch life.

Final Drives

Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, final drives provide high torque multiplication to further reduce drive train stress.

Full Floating Axles

Full floating axles relieve internal stresses and increase durability. Rolled splines also provide increased service life.

Power Train – Transmission – More power to the ground for greater productivity.

Mechanical Power Train

The Cat mechanical drive power train and power shift transmission provide unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads and drives with high rolling resistance.

Transmission

The Cat seven-speed planetary power shift transmission is matched with the direct-injection C18 engine to deliver constant power over a wide range of operating speeds.

Robust Design

Designed for rugged underground mining conditions, the proven planetary power shift transmission is built for long life between overhauls.

Lock Up Torque Converter

Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. When engaged, lock-up provides superior power train efficiency by delivering more power to the wheels.

Lock-Up Clutch

Quickly releases and re-engages to reduce power train torque loads for smoother shifting, long life and a more comfortable ride.

Smooth Shifting

Individual clutch modulation provides smooth clutch engagements to optimize performance and extend clutch life.

Final Drives

Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, final drives provide high torque multiplication to further reduce drive train stress.

Full Floating Axles

Full floating axles relieve internal stresses and increase durability. Rolled splines also provide increased service life.

Engine/Power Train Integration

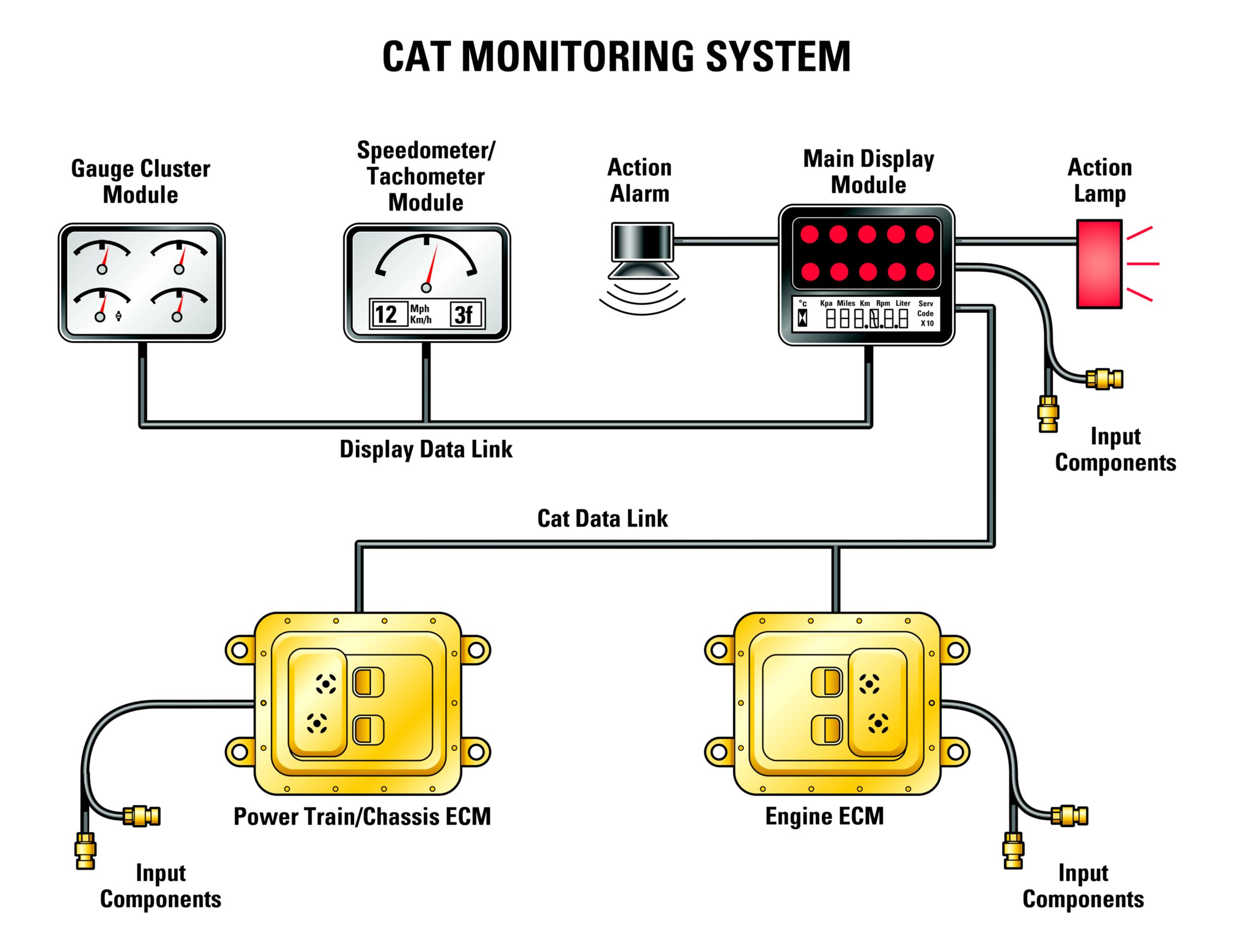

Cat Data Link

Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs.

- Controlled Throttle Shifting – Regulates engine RPM, torque converter lock-up and transmission clutch engagement for smoother shifts and longer component life.

- Economy Shift Mode – Decreases fuel consumption, lowers noise levels and potentially longer engine life.

- Directional Shift Management – Regulates engine speed to prevent damage caused by high speed directional changes.

- Body-up Shift Inhibitor – Prevents the transmission from shifting above a pre-programmed gear without the body fully lowered.

Electronic Technician (Cat ET)

Cat ET service tool provides service technicians with easy access to stored diagnostic data through Cat Data Link to simplify problem diagnosis and increase availability.

Overspeed Protection

The Automatic Retarder Control (ARC) system provides engine overspeed protection. The ARC will engage the brakes if the following conditions exist at the same time:

- An unsafe engine speed is reached.

- The ARC on/off switch is in the ON position or the OFF position.

- The throttle is being depressed by the operator.

Engine/Power Train Integration – Intelligent electronics for overall optimal performance.

Cat Data Link

Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs.

- Controlled Throttle Shifting – Regulates engine RPM, torque converter lock-up and transmission clutch engagement for smoother shifts and longer component life.

- Economy Shift Mode – Decreases fuel consumption, lowers noise levels and potentially longer engine life.

- Directional Shift Management – Regulates engine speed to prevent damage caused by high speed directional changes.

- Body-up Shift Inhibitor – Prevents the transmission from shifting above a pre-programmed gear without the body fully lowered.

Electronic Technician (Cat ET)

Cat ET service tool provides service technicians with easy access to stored diagnostic data through Cat Data Link to simplify problem diagnosis and increase availability.

Overspeed Protection

The Automatic Retarder Control (ARC) system provides engine overspeed protection. The ARC will engage the brakes if the following conditions exist at the same time:

- An unsafe engine speed is reached.

- The ARC on/off switch is in the ON position or the OFF position.

- The throttle is being depressed by the operator.

Cat Brake System

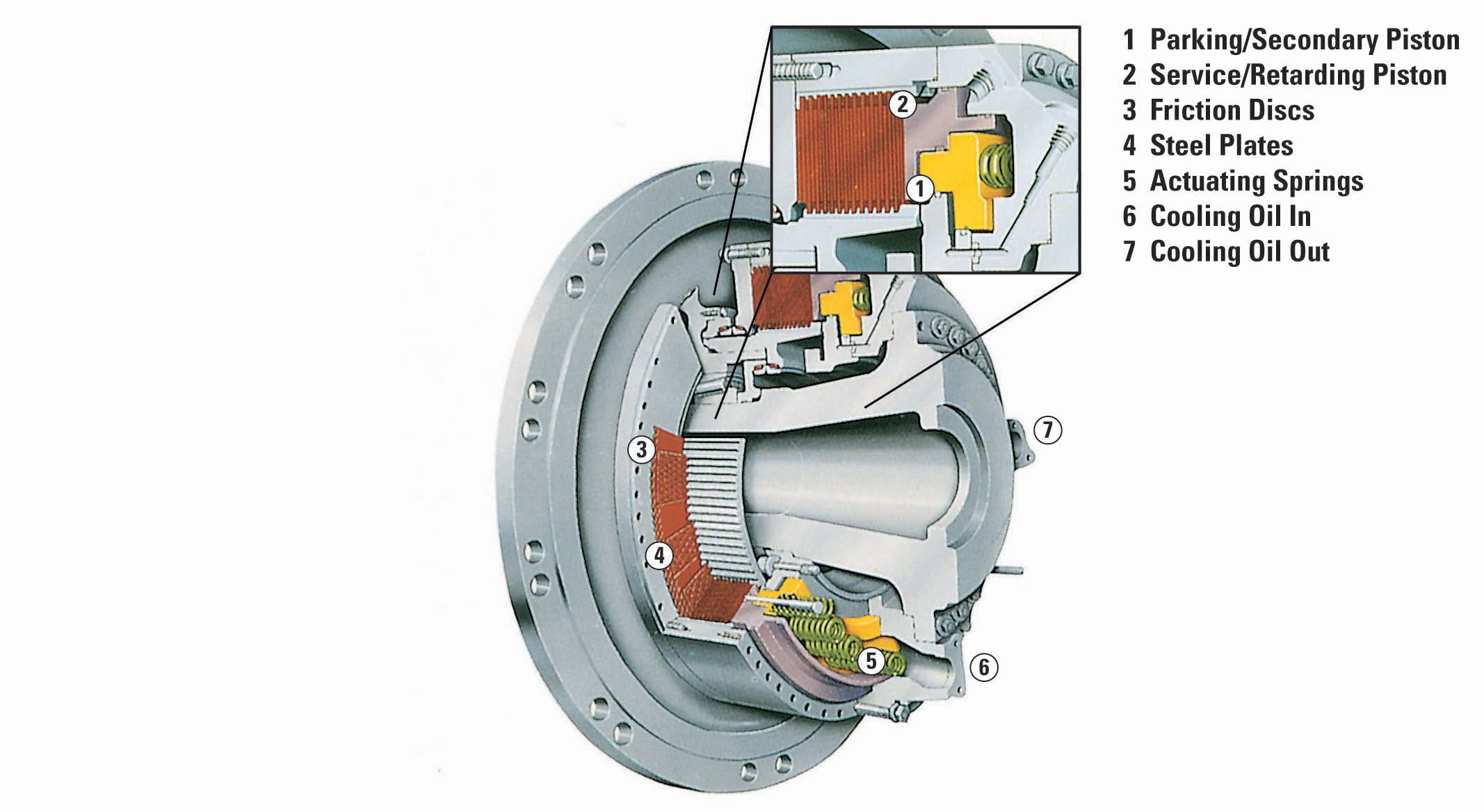

Integrated Braking System

The Cat oil-cooled braking system delivers reliable performance and control in the most extreme underground mining conditions. The integrated system combines the service, secondary, parking brake and retarding functions in the same robust system for optimum braking efficiency.

Oil-Cooled Multiple Disc Brakes

Four-wheel, forced oil-cooled, multiple disc service brakes are continuously cooled by a water-to-oil heat exchangers for non-fade braking and retarding performance. They are also completely enclosed to prevent contamination and reduce maintenance.

Automatic Retarder Control (ARC)

Electronically controls retarding on grade to maintain optimum engine RPM and oil cooling. Additional braking may be applied using the manual retarder or the brake pedal. ARC also allows the operator to maintain optimum engine speeds for faster downhill hauls and greater productivity. The ARC automatically activates when engine speed exceeds factory preset levels.

Superior Control

Automatic brake modulation offers a smoother ride and greater control, allowing the operator to concentrate on driving.

Cat Brake System – Superior control for operator confidence.

Integrated Braking System

The Cat oil-cooled braking system delivers reliable performance and control in the most extreme underground mining conditions. The integrated system combines the service, secondary, parking brake and retarding functions in the same robust system for optimum braking efficiency.

Oil-Cooled Multiple Disc Brakes

Four-wheel, forced oil-cooled, multiple disc service brakes are continuously cooled by a water-to-oil heat exchangers for non-fade braking and retarding performance. They are also completely enclosed to prevent contamination and reduce maintenance.

Automatic Retarder Control (ARC)

Electronically controls retarding on grade to maintain optimum engine RPM and oil cooling. Additional braking may be applied using the manual retarder or the brake pedal. ARC also allows the operator to maintain optimum engine speeds for faster downhill hauls and greater productivity. The ARC automatically activates when engine speed exceeds factory preset levels.

Superior Control

Automatic brake modulation offers a smoother ride and greater control, allowing the operator to concentrate on driving.

Operator Comfort

Protective Structure

Integral to the cab and frame, both the Rollover Protective Structure (ROPS) and Falling Objects Protective Structure (FOPS) are resiliently mounted to the mainframe to isolate the operator from vibration for a more comfortable ride.

Optional Enclosed Cab

Optional sound-suppressed ROPS cab provides a quiet, secure and comfortable air-conditioned working environment with fresh, pressurized, temperature-controlled air circulation.

Suspension Seat

Ergonomic, fully adjustable suspension seat provides optimal operator comfort. Thick cushions reduce pressure on lower back and thighs. Wide, retractable seat belts provide a secure, comfortable restraint.

Steering Column

Comfort wheel with tilt steering provides a comfortable driving position, secure grip and greater control.

Monitoring System

Cat Electronic Monitoring System (Cat EMS) continuously provides critical machine data to keep the machine performing at top production levels. Displays are backlit for easy viewing.

Operator Comfort – Ergonomically designed for all-day comfort, control and productivity.

The AD45B operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. All controls, levers, switches and gauges are positioned to maximize productivity and minimize operator fatigue.

Protective Structure

Integral to the cab and frame, both the Rollover Protective Structure (ROPS) and Falling Objects Protective Structure (FOPS) are resiliently mounted to the mainframe to isolate the operator from vibration for a more comfortable ride.

Optional Enclosed Cab

Optional sound-suppressed ROPS cab provides a quiet, secure and comfortable air-conditioned working environment with fresh, pressurized, temperature-controlled air circulation.

Suspension Seat

Ergonomic, fully adjustable suspension seat provides optimal operator comfort. Thick cushions reduce pressure on lower back and thighs. Wide, retractable seat belts provide a secure, comfortable restraint.

Steering Column

Comfort wheel with tilt steering provides a comfortable driving position, secure grip and greater control.

Monitoring System

Cat Electronic Monitoring System (Cat EMS) continuously provides critical machine data to keep the machine performing at top production levels. Displays are backlit for easy viewing.

Truck Body Systems

Cat Truck Bodies

Caterpillar offers two specific body styles for the most efficient hauling solutions at the lowest cost-per-ton.

- Dump Body

- Ejector Body

Body Selection

Selection of the right body depends on material, haul road, and dump conditions. The better the match of body to application, the greater the efficiency. Your Cat dealer can help you select the right body system for your site specific application.

Body Design

Cat truck bodies are designed for optimal strength, capacity and durability. Drawing on years of experience in truck body design, Cat Truck Bodies are designed for long service life and low cost per ton.

Body/Chassis Integration

Cat truck bodies are designed and matched with the integrated chassis system for optimum structural reliability, durability and long life.

Fast Hoist Cycle Times

Single-stage hoist cylinders provide fast dump cycle times of 16 seconds for raise and 21 seconds for lower.

Truck Payload Management System (TPMS)

The optional TPMS system calculates the payload the truck is carrying and determines truck cycle times.

Truck Body Systems – Rugged performance and reliability in tough underground mining applications.

Cat Truck Bodies

Caterpillar offers two specific body styles for the most efficient hauling solutions at the lowest cost-per-ton.

- Dump Body

- Ejector Body

Body Selection

Selection of the right body depends on material, haul road, and dump conditions. The better the match of body to application, the greater the efficiency. Your Cat dealer can help you select the right body system for your site specific application.

Body Design

Cat truck bodies are designed for optimal strength, capacity and durability. Drawing on years of experience in truck body design, Cat Truck Bodies are designed for long service life and low cost per ton.

Body/Chassis Integration

Cat truck bodies are designed and matched with the integrated chassis system for optimum structural reliability, durability and long life.

Fast Hoist Cycle Times

Single-stage hoist cylinders provide fast dump cycle times of 16 seconds for raise and 21 seconds for lower.

Truck Payload Management System (TPMS)

The optional TPMS system calculates the payload the truck is carrying and determines truck cycle times.

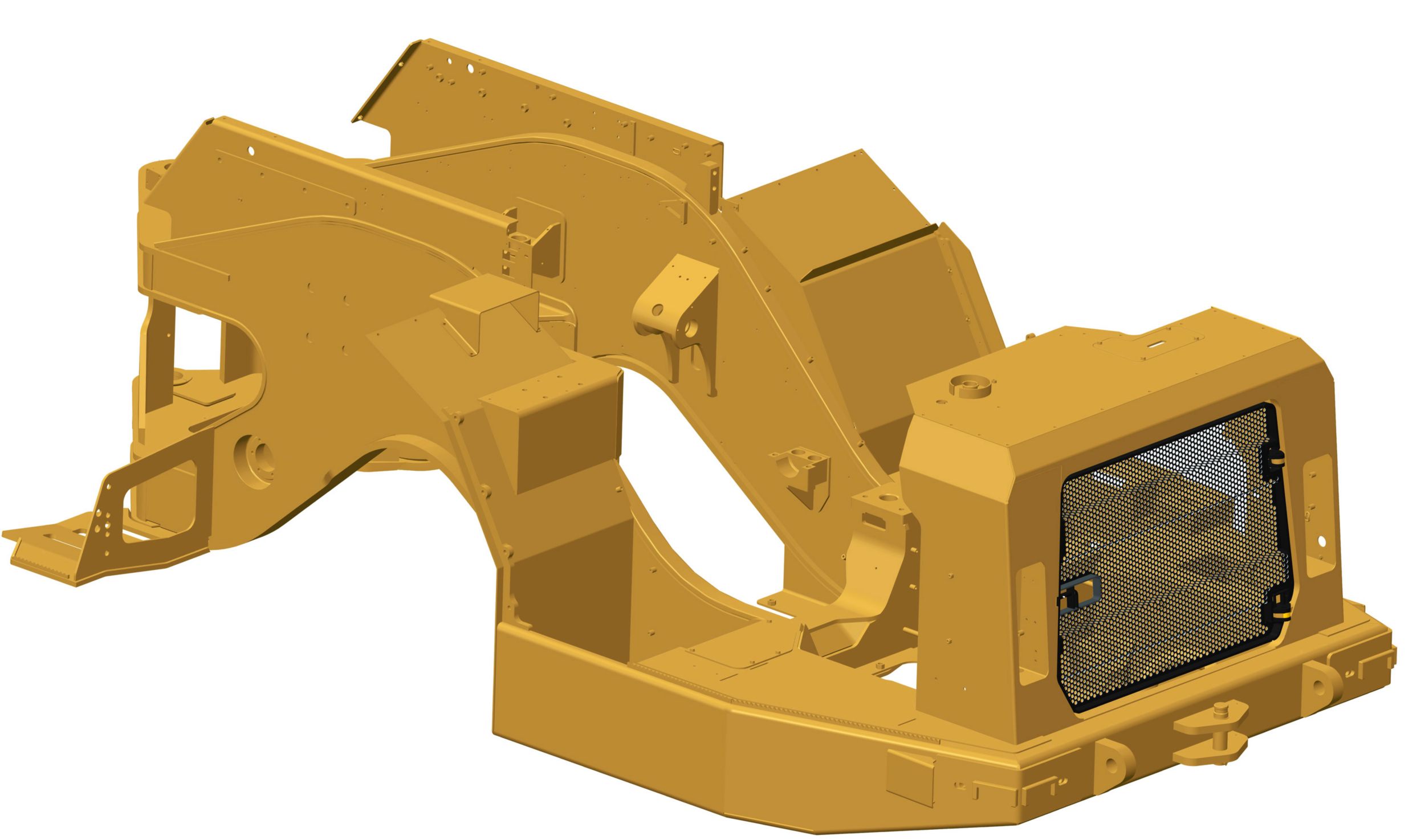

Structures

Frame Design

The frame uses box-section design with stiff frame beams to resist twisting forces. Materials and weld joints are matched to optimize the structural life of the frame.

Articulating/Oscillating Hitch

This system provides steering and oscillation and enables the truck to maintain all wheel ground contact in rough terrain.

Suspension System

Two independent variable rebound suspension cylinders dissipate haul road forces for longer frame life and a comfortable ride.

Structures – Rugged Cat structures – the backbone of the AD45B’s durability.

Frame Design

The frame uses box-section design with stiff frame beams to resist twisting forces. Materials and weld joints are matched to optimize the structural life of the frame.

Articulating/Oscillating Hitch

This system provides steering and oscillation and enables the truck to maintain all wheel ground contact in rough terrain.

Suspension System

Two independent variable rebound suspension cylinders dissipate haul road forces for longer frame life and a comfortable ride.

Serviceability

Service Access

Easy access to daily service points simplifies servicing and reduces time spent on regular maintenance procedures.

Ground-Level Access

Allows convenient servicing to all tanks, filters, lubrication points and compartment drains. Electric fuel priming. Remote mounted fuel filters for easier serviceability.

Air Filters

Radial seal air filters are easy to change, reducing time required for air filter maintenance.

Sight Gauges

Fluid level checks are made easier with sight gauges.

Diagnostics

Cat Electronic Technician (Cat ET) service tool enables quick electronic diagnosis of machine performance and key diagnostic data for effective maintenance and repairs.

Sealed Electrical Connectors

Electrical connectors are sealed to lock out dust and moisture. Harnesses are covered for protection. Wires are color and number coded for easy diagnosis and repair.

Scheduled Oil Sampling

S·O·SSM helps avoid minor repairs becoming major ones. Sample point adapters fitted standard to machine.

Serviceability – More time for production.

Service Access

Easy access to daily service points simplifies servicing and reduces time spent on regular maintenance procedures.

Ground-Level Access

Allows convenient servicing to all tanks, filters, lubrication points and compartment drains.

Electric fuel priming. Remote mounted fuel filters for easier serviceability.

Air Filters

Radial seal air filters are easy to change, reducing time required for air filter maintenance.

Sight Gauges

Fluid level checks are made easier with sight gauges.

Diagnostics

Cat Electronic Technician (Cat ET) service tool enables quick electronic diagnosis of machine performance and key diagnostic data for effective maintenance and repairs.

Sealed Electrical Connectors

Electrical connectors are sealed to lock out dust and moisture. Harnesses are covered for protection. Wires are color and number coded for easy diagnosis and repair.

Scheduled Oil Sampling

S·O·SSM helps avoid minor repairs becoming major ones. Sample point adapters fitted standard to machine.

Customer Support

Dealer Capability

Cat dealers will provide the level of support you need, on a global scale. Dealer expert technicians have the knowledge, experience, training and tooling to handle your repair and maintenance needs, when and where you need them.

Product Support

When Cat products reach the field, they are supported 24/7 by a worldwide network of reliable and prompt parts distribution facilities, dealer service centers, and technical training facilities to keep your equipment up and running.

Service Support

Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Cat dealers will be with you every step of the way with its unsurpassed worldwide parts support, trained technicians and customer support agreements.

Technology Products

Cat dealers offer a range of advanced technology products designed to improve efficiency, productivity and lower costs. VIMS™ Gen 3 option available from factory.

Replacement

Repair or rebuild? Your Cat dealer can help you evaluate the costs so you can make the right choice.

Customer Support – Cat dealer services keep underground mining equipment productive.

Dealer Capability

Cat dealers will provide the level of support you need, on a global scale. Dealer expert technicians have the knowledge, experience, training and tooling to handle your repair and maintenance needs, when and where you need them.

Product Support

When Cat products reach the field, they are supported 24/7 by a worldwide network of reliable and prompt parts distribution facilities, dealer service centers, and technical training facilities to keep your equipment up and running.

Service Support

Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Cat dealers will be with you every step of the way with its unsurpassed worldwide parts support, trained technicians and customer support agreements.

Technology Products

Cat dealers offer a range of advanced technology products designed to improve efficiency, productivity and lower costs. VIMS™ Gen 3 option available from factory.

Replacement

Repair or rebuild? Your Cat dealer can help you evaluate the costs so you can make the right choice.

Safety

Product Safety

Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and systems designs.

Engine Shutoff Switch

A secondary engine shutoff switch is located at ground level.

Integral ROPS Cab

Integral to the cab and frame, the ROPS is resiliently mounted to the frame to isolate the operator from vibration for a more comfortable ride.

Brake Systems

Four corner oil-cooled braking system provides excellent control. The service brakes and retarding system are actuated by modulated hydraulic pressure, while the parking brake function is spring applied and hydraulic released. This system assures braking in the event of loss of hydraulic pressure.

Operator Present System

Automatically engages parking brake, neutralizes steering, implement and transmission control, and shuts down the engine in the event the operator fails to apply the park brake prior to exiting the cab.

Standard Safety Features

Anti-skid upper deck surfaces, upper deck handrails, 3-point cabin and machine access, push out safety glass, excellent visibility, suspension seat, passenger/training seat, inertia reel retractable belts, steering frame lock, rear window guard, body retaining pins, automatic retarder control, exhaust heat shielding and firewall fitted standard, hitch hydraulic hoses – burst protection sleeves fitted, tailgate retaining pins (ejector body), alternate exit via windows, ground level compartment sight glasses, hot and cold side of engine.

SAFETY.CAT.COM™

For more complete information on safety, please visit www.safety.cat.com.

Safety – Designed with safety as the first priority.

Product Safety

Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and systems designs.

Engine Shutoff Switch

A secondary engine shutoff switch is located at ground level.

Integral ROPS Cab

Integral to the cab and frame, the ROPS is resiliently mounted to the frame to isolate the operator from vibration for a more comfortable ride.

Brake Systems

Four corner oil-cooled braking system provides excellent control. The service brakes and retarding system are actuated by modulated hydraulic pressure, while the parking brake function is spring applied and hydraulic released. This system assures braking in the event of loss of hydraulic pressure.

Operator Present System

Automatically engages parking brake, neutralizes steering, implement and transmission control, and shuts down the engine in the event the operator fails to apply the park brake prior to exiting the cab.

Standard Safety Features

Anti-skid upper deck surfaces, upper deck handrails, 3-point cabin and machine access, push out safety glass, excellent visibility, suspension seat, passenger/training seat, inertia reel retractable belts, steering frame lock, rear window guard, body retaining pins, automatic retarder control, exhaust heat shielding and firewall fitted standard, hitch hydraulic hoses – burst protection sleeves fitted, tailgate retaining pins (ejector body), alternate exit via windows, ground level compartment sight glasses, hot and cold side of engine.

SAFETY.CAT.COM™

For more complete information on safety, please visit www.cat.com/safety.

Standard Equipment

-

ELECTRICAL

- 12V power supply in cab

- 12V power supply in cab

- Alternator, 95-amp

- Alternator, 95-amp

- Auxiliary start receptacle

- Auxiliary start receptacle

- Battery disconnect switch, ground level

- Battery disconnect switch, ground level

- Circuit breaker, 80-amp

- Circuit breaker, 80-amp

- Corrosive protection spray

- Corrosive protection spray

- Diagnostic connector

- Diagnostic connector

- Electric starting, 24V

- Electric starting, 24V

-

Engine shutdown switch, ground level

– Front left hand side

-

Engine shutdown switch, ground level

– Front left hand side

-

Lighting

– Brake and tail light, LED

– Headlights with dimmer switch, halogen

– Rear work light (cab mounted), halogen

– Reversing lights, halogen

-

Lighting

– Brake and tail light, LED

– Headlights with dimmer switch, halogen

– Rear work light (cab mounted), halogen

– Reversing lights, halogen

- Low maintenance batteries

- Low maintenance batteries

- Reversing alarm

- Reversing alarm

- Starting and charging system

- Starting and charging system

-

OPERATOR ENVIRONMENT

- Cat Electronic Monitoring System (Cat EMS)

- Cat Electronic Monitoring System (Cat EMS)

- Electric horns

- Electric horns

-

Gauges

– Engine coolant temperature

– Transmission coolant temperature

– Hydraulic oil temperature

– Fuel level

– Speedometer

– Tachometer

-

Gauges

– Engine coolant temperature

– Transmission coolant temperature

– Hydraulic oil temperature

– Fuel level

– Speedometer

– Tachometer

-

Indicator lights

– Alert warning light

– Body up position warning

– High beam

– Residual brake pressure warning

– Retarder application

– Turn signal

-

Indicator lights

– Alert warning light

– Body up position warning

– High beam

– Residual brake pressure warning

– Retarder application

– Turn signal

- Low hydraulic level warning

- Low hydraulic level warning

- Open operator station ROPS/FOPS structure

- Open operator station ROPS/FOPS structure

- Operator presence system (auto park brake)

- Operator presence system (auto park brake)

- Rearview mirrors

- Rearview mirrors

- Suspension seat Cat Comfort TLV2 with retractable seat belt

- Suspension seat Cat Comfort TLV2 with retractable seat belt

- Trainer/passenger seat and seat belt

- Trainer/passenger seat and seat belt

- Tilt/telescopic steering wheel

- Tilt/telescopic steering wheel

- Turn signal indicators

- Turn signal indicators

-

POWER TRAIN

- Cat C18 ATAAC diesel engine, 6-cylinder

- Cat C18 ATAAC diesel engine, 6-cylinder

- Automatic brake retarder control

- Automatic brake retarder control

- Auto shift transmission 7 speed forward/2 speed reverse

- Auto shift transmission 7 speed forward/2 speed reverse

- Control throttle shifting

- Control throttle shifting

- Engine air intake precleaner

- Engine air intake precleaner

- Electric fuel priming pump

- Electric fuel priming pump

- Exhaust, turbo compartment shielding

- Exhaust, turbo compartment shielding

- Four wheel drive

- Four wheel drive

- Long life coolant

- Long life coolant

- Programmable ground speed limiting

- Programmable ground speed limiting

- Programmable gear block out with tray up

- Programmable gear block out with tray up

- Radiator cap manual release

- Radiator cap manual release

- Radiator, cross flow

- Radiator, cross flow

- SAFR™ full hydraulic enclosed wet, multiple-disc brakes, oil cooled

- SAFR™ full hydraulic enclosed wet, multiple-disc brakes, oil cooled

- Torque converter, standard with automatic lockup

- Torque converter, standard with automatic lockup

-

OTHER STANDARD EQUIPMENT

- Body, dump, (21.3 m³/27.9 yd³)

- Body, dump, (21.3 m³, 27.9 yd³)

- Catalytic exhaust purifier/muffler group

- Catalytic exhaust purifier/muffler group

- Centralized lubrication points

- Centralized lubrication points

- Decals, international picto graphics

- Decals, international picto graphics

- Dual fuel tanks

- Dual fuel tanks

- Engine and transmission belly guards

- Engine and transmission belly guards

- Fenders, front, rear flaps

- Fenders, front, rear flaps

- Fire wall

- Fire wall

- Fuel system manual shut off tap

- Fuel system manual shut off tap

- Front axle suspension

- Front axle suspension

- Frame lifting lugs

- Frame lifting lugs

- Front and rear tow pin

- Front and rear tow pin

- Front rubber bumpers

- Front rubber bumpers

- Hand hold (access on/off top deck)

- Hand hold (access on/off top deck)

- Hitch, articulated and oscillated

- Hitch, articulated and oscillated

- Operator and Maintenance Manual, English

- Operation and Maintenance Manual – English and other applicable local languages to select

-

S·O·S port

– Coolant

– Engine oil

– Hydraulic oil

– Transmission oil

-

S·O·S port

– Coolant

– Engine oil

– Hydraulic oil

– Transmission oil

- Swing out radiator grill

- Swing out radiator grill

- Tires and rims: A tire must be selected from the mandatory attachments section of the machine price list. Base machine price includes a standard tubeless rim allowance only.

- Tires and rims: A tire must be selected from the mandatory attachments section of the machine price list. Base machine price includes a standard tubeless rim allowance only.

Optional Equipment

-

OPTIONAL EQUIPMENT

-

Battery shutdown

– Ground level isolation, in cab isolation switch

– Ground level isolation, engine shutdown switch

– Ground level isolation, in cab isolation, engine shutdown switch

-

Battery shutdown

– Ground level isolation, in cab isolation switch

– Ground level isolation, engine shutdown switch

– Ground level isolation, in cab isolation, engine shutdown switch

-

Body dump

– Body, (18.0 m³/23.5 yd³)

– Body, (25.1 m³/32.8 yd³)

-

Body dump

– Body, (18.0 m³, 23.5 yd³)

– Body, (25.1 m³, 32.8 yd³)

-

Body ejector

– Ejector, (22.9 m³/30.0 yd³)

-

Body ejector

– Ejector, (22.9 m³, 30.0 yd³)

-

Body liners, impact and/or wear

– 10 mm (0.4"), body, dump (18.0 m³/23.5 yd³)

– 10 mm (0.4"), body, dump (21.3 m³/27.9 yd³)

– 10 mm (0.4"), body, dump (25.1 m³/32.8 yd³)

– 10 mm (0.4"), body, ejector, (22.9 m³/30.0 yd³)

-

Body liners, impact and/or wear

– 10 mm (0.4"), body, dump (18.0 m³, 23.5 yd³)

– 10 mm (0.4"), body, dump (21.3 m³, 27.9 yd³)

– 10 mm (0.4"), body, dump (25.1 m³, 32.8 yd³)

– 10 mm (0.4"), body, ejector, (22.9 m³, 30.0 yd³)

-

Body wear plate, external

– 16 mm (0.62"), body, dump (18.0 m³/23.5 yd³)

– 16 mm (0.62"), body, dump (21.3 m³/27.9 yd³)

– 16 mm (0.62"), body, dump (25.1 m³/32.8 yd³)

-

Body wear plate, external

– 16 mm (0.62"), body, dump (18.0 m³, 23.5 yd³)

– 16 mm (0.62"), body, dump (21.3 m³, 27.9 yd³)

– 16 mm (0.62"), body, dump (25.1 m³, 32.8 yd³)

- Brake pressure gauges

- Brake pressure gauges

- Camera, color rear facing

- Camera, color rear facing

- Cover, anti vandalism for shipping

- Cover, anti vandalism for shipping

-

Engine options

– Diesel particulate filter (for use with VR engine only)

– Engine, Ventilation Reduction (VR)

– Tier 3

-

Engine options

– Engine, Ventilation Reduction (VR)

– Equivalent to Tier 3

– After-treatment options (for use with VR Engine only)- DPF (Flow Through) Filter

-

Fast fill system

– Coolant

– Engine oil

– Fuel (dual tanks)

– Hydraulic oil

– Transmission oil

-

Fast fill system

– Coolant

– Engine oil

– Fuel (dual tanks)

– Hydraulic oil

– Transmission oil

-

Fire suppression system

– Ansul, dry powder

– Foam, water based

-

Fire suppression system

– Ansul, dry powder

– Foam, water based

-

Fluids

– Arctic fuel

– Arctic coolant

-

Fluids

– Arctic fuel

– Arctic coolant

-

Lighting

– Headlights with dimmer switch, LED

– Rear work light (cab mounted), LED

– Reversing lights, LED

-

Lighting

– Headlights with dimmer switch, LED

– Rear work light (cab mounted), LED

– Reversing lights, LED

-

Lubrication system

– Automatic, dump or ejector body

– Centralized, ejector body

-

Lubrication system

– Automatic, dump or ejector body

– Centralized, ejector body

-

Mine transfer

– Mine transfer ready front frame (tack welded)

– Mine transfer ready dump body (tack welded)

– Mine transfer ready ejector body (tack welded)

-

Mine transfer

– Mine transfer ready front frame (tack welded)

– Mine transfer ready dump body (tack welded)

– Mine transfer ready ejector body (tack welded)

-

Operators station ROPS/FOPS enclosed

– Air conditioning

– Cab pressurizer and filter

– Dome light

– Heater

– Radio ready compartment for radio and speakers

– Sun visor

– Window, sliding cab door

-

Operators station ROPS/FOPS enclosed

– Air conditioning

– Cab pressurizer and filter

– Dome light

– Heater

– Radio ready compartment for radio and speakers

– Sun visor

– Window, sliding cab door

-

Operator and Maintenance Manual

– Chinese

– Indonesian

– French

– Portuguese

– Russian

– Spanish

-

Park brake switch engagement

– Push to apply

– Pull to apply

-

Park brake switch engagement

– Push to apply

– Pull to apply

-

Payload

– Truck Payload Measurement System (TPMS)

– Remote display for TPMS

-

Payload

– Truck Payload Measurement System (TPMS)

– Remote display for TPMS

- Reflective tape

- Reflective tape

-

Rims

– Rim identification numbering

– Spare, tubeless

-

Rims

– Rim identification numbering

– Spare, tubeless

-

Seat

– Suspension seat Cat Comfort TLV2, vinyl

– Suspension seat tee, mechanical

-

Seat

– Suspension seat Cat Comfort TLV2, vinyl

– Suspension seat tee, mechanical

-

Seat cover

– Tee and Cat Comfort TLV2

– Seat cover, companion

-

Seat cover

– Tee and Cat Comfort TLV2

– Seat cover, companion

- Secondary steering system

- Secondary steering system

-

Service tools

– Collet jacking bolts, dump or ejector

– Diagnostics box

– Hoist cylinder supports (for body removal)

– Brake wear gauge

– Reference parts manual for additional tooling available

-

Service tools

– Collet jacking bolts, dump or ejector

– Diagnostics box

– Hoist cylinder supports (for body removal)

– Brake wear gauge

– Reference parts manual for additional tooling available

-

Switches

– Engine shutdown, fire suppression activation

– Idle timer

– Engine shutdown, fire suppression activation/idle timer

-

Switches

– Engine shutdown, fire suppression activation

– Idle timer

– Engine shutdown, fire suppression activation/idle timer

-

Technology

– Vital Information Management System (VIMS) Gen 3

-

Technology

– Vital Information Management System (VIMS) Gen 3

-

Tire arrangements

– Tire, 29.5 × R29 VSNT Bridgestone

– Tire, 29.5 × R29 VSDL Bridgestone

-

Tire arrangements

– Tire, 29.5 × R29 VSNT Bridgestone

– Tire, 29.5 × R29 VSDL Bridgestone

- Torque converter, high altitude, 3000 m (9,842 ft) and up

- Torque converter, high altitude, 3000 m (9,842 ft) and up

- NOTE: Not all features are available in all regions. See your Cat dealer for more information.

- NOTE: Not all features are available in all regions. See your Cat dealer for more information.

-

Battery shutdown